Hella Pagid brake pads

The Hella Pagid Brake Systems brake pads range comprises more than 2,300 items, manufactured in line with 50 different recipes. These are designed to precisely reflect the respective requirements of the various vehicle types, brake systems, engine outputs, driving loads, and braking characteristics. What's more, Hella Pagid Brake Systems disc brake pads are found in almost 100 % of the vehicles on the roads of Western Europe.

Tests are hugely important at Hella Pagid Brake Systems. Products are tested, not only at the group's own research and development center, but also on the roads under real conditions. The standards are always the exacting requirements and performance specifications of the vehicle and braking system manufacturers. The program puts our brake pads through up to 300,000 test kilometers and 1,000 hours of test bed testing before releasing them for serial production. For Hella Pagid Brake Systems, maximum safety and performance are key. An overview of all our product benefits is available here:

Our philosophy

We need no better reason for developing every brake pads specifically to the very individual needs of every single vehicle. A portfolio of 50 different brake pads mixes guarantees a brake pads suited to every vehicle. During development work, to achieve maximum braking performance, we also consider the direct friction partner, i.e. the brake disc.

All this means that it takes on average two years for us to develop a new friction material.

Discover more about the process involved in producing a brake pad.

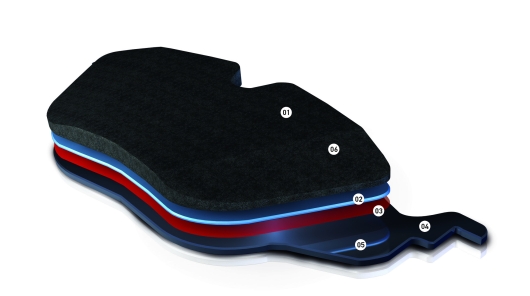

The anatomy of a brake pad

The friction material has to fulfil extremely demanding tasks and therefore needs to be precisely tailored to the relevant area of use. The competitive advantage here is provided by the 50 different formulations mentioned above.

2. INTERMEDIATE LAYER

The intermediate layer possesses almost universal properties. It improves hardness, crack resistance, and the comfort-related properties of the brake pad and also reduces heat transfer, ensures a high degree of shear protection, and even optimizes noise behavior.

3. ADHESIVE

The specially developed adhesive permanently connects the pad material to the carrier plate and also guarantees particularly high shear resistance.

4. CARRIER PLATE

Not one-size-fits-all but brake-specific designs in different grades of steel determine the quality of our carrier plates. In every case their quality, strength, and tolerances fulfil the extremely high requirements of the particular braking system: the best conditions for trouble-free operation and a long lifetime.

5. POWDER COATING

The final touch for our brakes is the powder coating. It gives the finished product a spotless finish as well as reliable corrosion protection.

6. SECONDARY MEASURES

These measures and devices effect a further improvement in overall braking performance and driving comfort. They include, for example, the angled friction material.

Product advantages

Leading car manufacturers trust the quality of our original equipment. That goes for all segments. On the one hand, we provide equipment for high-performance sports cars such as the Porsche 911. On the other hand, we supply small cars like the Audi A1. We transfer this expertise to the independent aftermarket so that you always stop safely.

2. Production in the EU

Hella Pagid brake pads are mainly manufactured in the EU. We have utmost faith in the abilities of our staff and invest continuously in their training. This way we can guarantee consistently high quality and outstanding brake performance that you can trust.

3. 100% in-house production

Hella Pagid Brake Systems covers the entire development and production process. To have total control such as this gives us an invaluable competitive advantage. It means that we can be confident when we say that we offer only the best quality.

4. Hella Pagid far exceeds ECE-R90

Hella Pagid does not just fulfil this regulation, but surpasses it by a long way. For example, ECE-R90 does not test comfort or durability. We do this so we can offer you a true premium product

ECE-R90 is a legal guideline. It obligates every manufacturer to ensure that the quality of brake pads and brake shoes in free replacement parts retail does not deviate by more or less than 15% from that of the OE item.

5. Coverage

We cover 98% of the market in Western Europe with our brake pads. For you, this means that if you name your brake pad, we have it.

General brake pads production

2. Adhesive is applied to the pad back plate. This adhesive binds the back plate to the friction material or intermediate layer.

3. The friction material or intermediate layer is comprised from the various raw materials. The main job of the friction material is to ensure that the friction factor is stable under all operating conditions and with acceptable noise and wear behavior. If required, a 2mm thick intermediate layer is inserted between the friction material and the back plate. This intermediate layer helps to better bind the friction material to the back plate, provides thermal insulation, and reduces noise.

4. The friction material, together with the intermediate layer if present, is compressed onto the back plate so that the forward portion of the brake pad protrudes.

5. The brake pad is hardened.

6. The brake pads is ground to the working thickness.

7. Almost all brake pads are chamfered to improve comfort (reduce noise).

8. The brake pad is painted to protect against future corrosion.

9. The brake pads is identified with the required item information.

10. Extra accessories such as springs, damping plates, wear indicators, additional weights, etc. are mounted.

11. The brake pads is now complete and is packaged along with any additional loose accessories.

more